The expression of the dynamism and flexibility of our company places us at the forefront of evolving technologies. The continuous updating of our skills allows us to easily manage the most important technologies in the industry.

SAFETY

The world of machine safety is now managed by software. Today, dedicated programmable equipment controls and governs the devices that ensure machine safety and compliance with current regulations.

However, if the software does not comply with the required procedures and standards, it can itself become a cause of problems and accidents. Therefore, simply installing a 'safety PLC' is not enough to solve the issue. It is the software developed for these tools that truly gives meaning to the CE mark, which is so important yet sometimes underestimated.

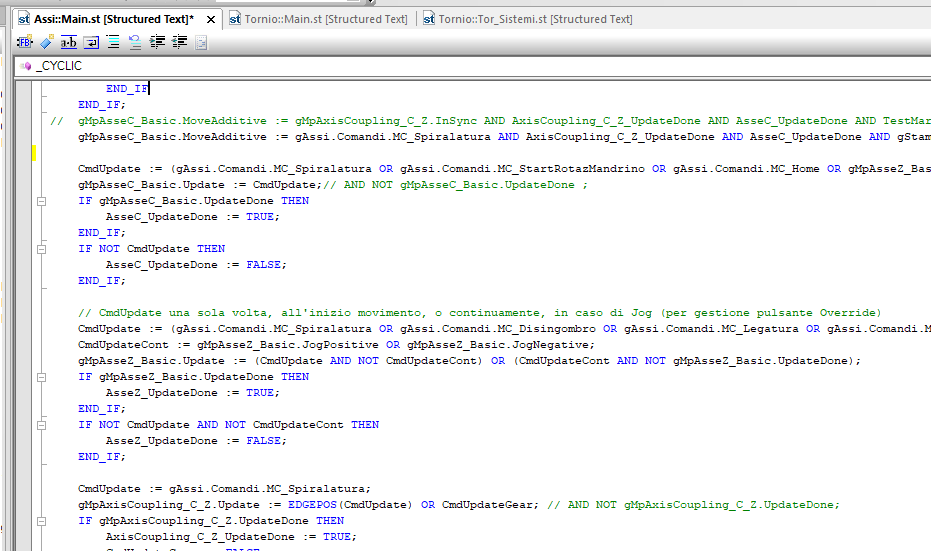

MOTION CONTROL

The close integration of mechanics, electronics, and computer science defines Motion Control, an important reference that covers many typical applications in the field of industrial automation. It includes all technologies that use electronic systems to control the movement of mechanical components (sliders, conveyors, flying cut-off units, multi-axis systems, etc.).

The evolution of the consumer goods market, now characterized by short life cycles and a high number of variants, has necessitated the development of flexible machines and production systems. Additionally, multiple different versions of the same machine are often required within very short timeframes. Much of this flexibility is achieved through Motion Control.

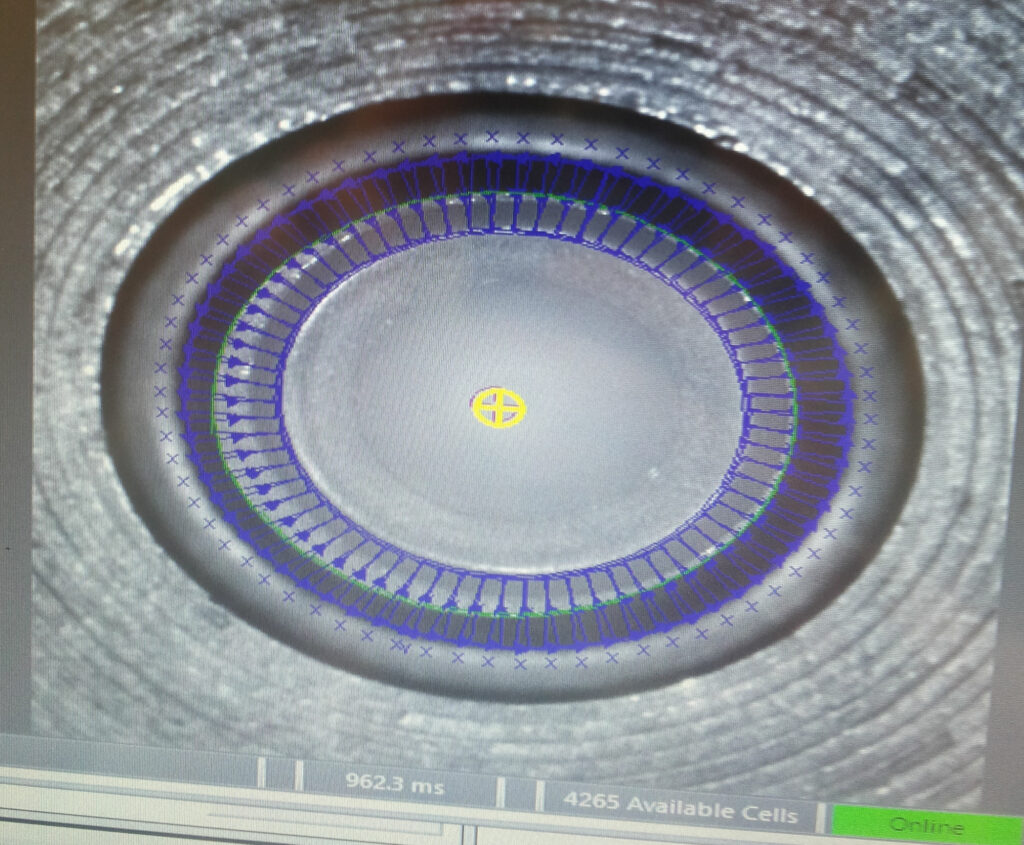

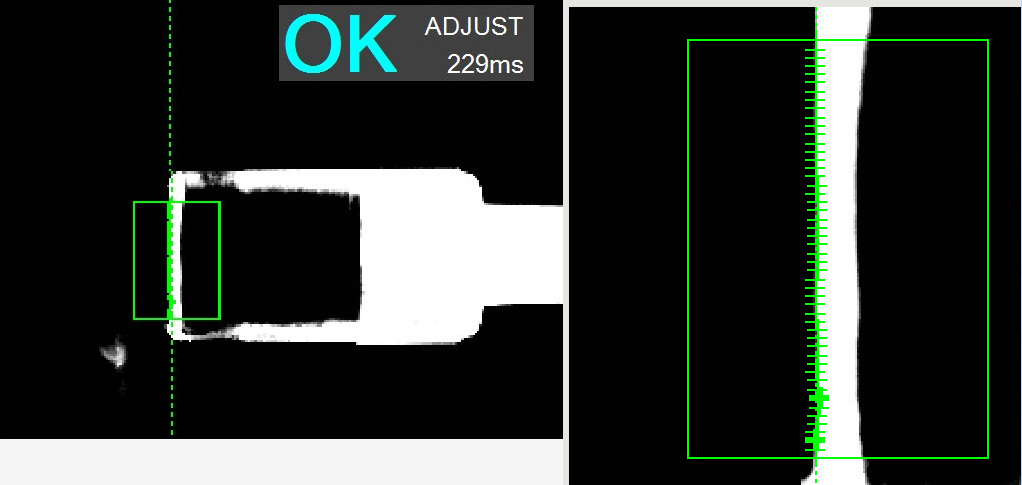

COMPUTER VISION

Increasingly flexible systems and machines obtain the best response from artificial vision systems in terms of control, inspection, and information processing required for the correct execution of processes. The versatility of these systems allows them to provide concrete solutions to control demands that would otherwise be unattainable.

The combination of image acquisition systems, optics, and appropriately designed lighting systems provides the possibility of obtaining efficient and versatile measurements and controls. The use of vision systems combined with the movements offered by robots and cobots effectively meets the increasingly important demands for efficiency, versatility, and flexibility that characterize modern automatic machines.

INDUSTRY 4.0

The concept of Industry 4.0 envisions the future of industry and production in which information technology (IT) will enhance competitiveness and efficiency by connecting all resources (data, people, and machinery) in the value chain. Smart manufacturing makes a factory intelligent by applying advanced information and communication systems and future-oriented technologies. The goal is to increase flexibility levels, reduce delivery times, enable small batch production, and allow for extensive product customization, which, as mentioned above, represents the added value for the customer.

Industry 4.0 makes it possible to collect and analyze information between machines, provide faster and more flexible responses, and also have more efficient processes capable of producing high-quality components at a lower cost. All these elements will consequently lead to increased productivity and industrial growth, thus changing the profile of the workforce.

ROBOT / COBOT

The evolution of robots finds its highest expression in cobots, no longer mere executors of simple repetitive tasks, but flexible machines capable of interacting and collaborating with human workers within a shared workspace, always in compliance with the highest safety standards.

Among other things, Industry 4.0 aims to create machinery that can interact with the human component of a company in such a way as to make work more efficient for both parties. This is why, despite being invented in the 1990s, cobots are now widely applied in various industrial solutions. Through the integration of vision systems, robots and cobots offer unimaginable flexibility and evolution possibilities in machines designed with conventional tools.